Sewing collars & leashes with an LK-1900BN bartacking machine

As mentioned on the collars & leashes page, I used a Singer 201-2 to sew collars for 2-3 years. Then I bought a Juki LK-1900BN bartacking machine (brochure, instruction manual, parts list & engineer's manual) which lets me go 5-10x faster. It has a sewing field of 1.57"w x 1.18"h (40 x 30mm). It can sew box-x patterns, but doesn't come with any.

Before buying

The machine has a steep learning curve (adjustments, options & settings). It takes time using it to get comfortable, find what works for you. You can watch YouTube videos. Watching a lot[1] of those (more than once) helped me feel much more comfortable when my machine arrived.

Before getting one of these, keep in mind it's incredibly heavy (110 lbs + the table). Having a table with wheels helps a lot. Industrial machines traditionally use a "k-leg table." Sometimes people add casters to that. But, that's kludgey (it raises the foot pedal too.). There are newer designs of tables with wheels (the foot pedal remains at the floor). I would try to get the machine with that. Usually the table is 48"w x 20"d. I was able to get my machine with a 36" wide. (I didn't need a full table because I have another table next to this one).

There is high-capacity bobbin version (-BNW) of this machine. If you're starting with the -BNH (heavy weight), then it's just four parts to convert to high-capacity.[2] The standard-sized bobbin works fine. Replacing the bobbin (and start one winding) doesn't take long after you get used to it. But, a large-capacity bobbin (lasting twice as long) is definitely nice. I didn't convert mine until I had it 2 years. If you don't think you could replace those parts yourself, consider having it done when you buy the machine.

Pre-loosen screws

I've never had a good relationship with screws. One of my greatest fears with this machine has been rounding off a screw's head (then needing special equipment to remove it). You should plan on investing in a good set of screwdriver bits, "hollow ground," (even multiple sets can help). Think ahead about the screws you may need to remove, and how accessible they are (if you need a right-angle ratcheting bit driver, stubby-handle screwdriver). Ask the seller what they recommend.

There are a few screws you'll probably need to remove sooner than later. I would ask the seller to loosen & re-tighten the following (with grease or anti-seize compound applied) so they'll be easier for you:

"work clamp face plate" screws (5)

You'll have to remove these screws to change the "work clamp feet." These are notoriously difficult to loosen. It has something to do with their anodized finish (binding with the anodized finish of the plate, the beveled mating surface). When they snap free, they spin so freely you'll think you snapped the head off.

Usually people heat over-tight screws. But, putting the arch in the freezer works much better for these. Leave it for hours (let it completely freeze to its core).

I bought additional arches, so I got more experience with this topic than you normally would. I spray some "Liquid Wrench" on the screws, then heat it with a heat gun. When cool, I put the arch in the freezer. The expansion before contraction of freezing may help. But, I wouldn't try to loosen while it's hot. It always snaps free easier when frozen. (If you try when it's hot, you're just risking rounding off the head in a way you wouldn't if you wait till it's frozen.). After a deep freeze, if the screws don't break free, I do it again (penetrating oil, heat, deep freeze for hours). I think it helps to strike the screwdriver with a hammer when frozen. (It may help when hot too. But trying to loosen when hot doesn't work as well as when frozen. I would only try to turn the screw when frozen. The odds of it breaking loose are much greater. Therefore, you're just increasing your risk of rounding off the head if you try to turn it when hot.). Cycling through hot/cold helps more than striking the screw (if you're not comfortable striking it).

You need a vice to do the above. Clamp it between some wood so you don't mar the arch. It's a good idea to buy a few spare screws (#SS2110930SP, desc: SCREW 11/64-40 L=8.7). You might partially round a slot. But, if the seller breaks these free for you, you'll have less potential need for spares.

"finger guard" setscrews (2)

These seem to be hard to turn due to thread-locking compound. Heat works better than freezing. What makes these risky is that they're tiny. You need a jeweler screwdriver (which aren't made for this kind of duty, they can snap if you turn too hard). Also, if you round the head off, it would be harder to fix because of the screw's size & being recessed.

To get enough torque, I clamped long-nose clamping pliers onto the screwdriver. With my thumb pushing hard against the end of the screwdriver, I rock the screwdriver with my other hand (using the clamp for grip). I rock back/forth very little and the screw will begin to give. (Trying to move it too much will break the tiny screwdriver). Cycling cold/hot might help. But, I wouldn't try to turn it while frozen. Heat & penetrating oil, rocking it back/forth is when there's more chance it will loosen. The key is to rock it back/forth. You might have to do that until it's all the way out (it can take a lot of time).

(Spares: #SS8080310TP, desc: SCREW 1/8-44 L=2.8)

"ball retainer" setscrew (1)

This one's not as bad as the prior two. It may need some penetrating oil & heat. (If that doesn't work, try it again after freezing).

The "ball retainer" actually retains a flat slider part. Prior versions of the 1900 used balls. The parts manual still refers to the retainer as if balls are still used (but it's not the same part #). You may need to adjust the retainer up/down. If too low the front of the arch will flex up/down too much. Too high you could get an E926 error when the machine initializes (the arch won't move freely enough).

(Spares: #SS8150510TP, desc: SCREW 15/64-28 L=4.7. I don't think you need a spare for that setscrew. But, I think it's easy to lose the "slider" #40142736 if you remove the arch. A spare might be handy to have.)

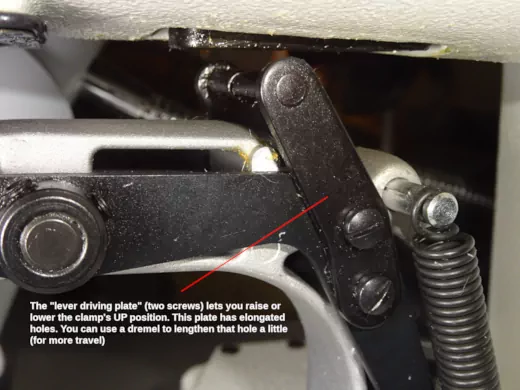

"lever driving plate" screws (4)

These screws are almost as difficult as the 5 faceplate screws above. Once again, it seems like it's the anodized surfaces under the screw head that binds to the anodized surface of the lifting levers. These break free easier when frozen (follow the advice for the faceplate screws).

These let you adjust the height of the "work clamp feet." This is mainly to make them level. But, you can adjust both sides 3/8" higher/lower.

(Spares: #SS7110740TP, desc: SCREW 11/64-40 L=7)

"needle plate" screws (4)

The reason I suggest pre-loosening these screws is because they're hard to access (with the machine's head above). Trying to turn them with a long screwdriver at an angle could round the slot. Using a shorter screwdriver could be awkward to hold & push down while turning. If you round one of these off, it would be hard to fix due to the lack of access.

The needle plate is more common to remove. You have to remove this to access the cutting knife (27) underneath. I had to remove it to replace the hook & shuttle driver (when upgrading to the high-capacity bobbin).

(Spares: #SM1040650TP, desc: SCREW M4 L=6)

"cloth feed presser plate" screws (6)

You'll have less reason to remove the presser plate. But, like the needle-plate screws: if you round one off a head, there's no access to drill it out. (They need to be tight or they'll vibrate loose. But, they may come from the factory excessively tight.)

One risk which may necessitate removing this plate: when you remove the arch, the "slider" (in the "ball retainer" cup above) may stick to the "slider sheet" above it (due to the grease on the sheet). I always worry it could fall off. If the "feed plate" (29) were removed, the slider could fall inside.

(Spares: SM1040650TP, desc: SCREW M4 L=6. Same as used for the needle plate.)

Note: the "feed plate" (29) screw was also stubborn like the face & lever-plate screws (it snaps free. The anodized finish between the screw head and washer binds like those screws.). Grease between the screw's head & washer helps. Eventually the anodized finish wears off enough that it stops doing it. (FYI: That screw has a 4mm allen-head which reduces the risk of rounding off. However, I felt like I got a slightly better fit using a 5/32" allen wrench.). You can buy allen wrenches with a ball-shape on the long end. Those are handy to quickly snug the plate (and the 5mm arch screw). Then use the short end (which shouldn't be ball-shaped) to fully tighten it.

Materials

You'll need Juki #2 oil (thicker than the #1 oil used with the DU-1181N, which I sew leash sleeves with).

The machine requires periodic greasing. It will display error code E220 when the machine's been used enough to require grease (I haven't reached it yet). The instruction manual (pg 54, "replenishing the designated places with grease") & engineer's manual (pg 132, "grease-up procedures for the specified position") discusse it. You'll need a tube of Juki Grease A (400-06323) for that.

There are other places you'll need to grease as needed. The engineer manual (pg 121, "parts to which grease is applied") shows all of the possible locations. But, what you'll grease the most are 1) the plate above the arch (which the ball retainer slides against). The clamp legs (sliding under the arch's face plate). The manual shows that you don't need "Grease A" for all those things. Pg 120 (greasing parts) discusses the types of grease to use. I think for these things, you can use ordinary SuperLube silicone lubricating grease found at the hardware store. You should ask the seller of the machine. (Grease "A" is expensive. Use it only where the manual requieres it.).

You'll need spare bobbins (#138-12102. I believe they're "Style A, class 15." I don't know for sure. The large-capacity bobbin is #B180-621-0D00.). If you sew both Tex 70 & 90 thread, then you need another bobbin case (#B1828-980-0BB. Or, the large-capacity B1828-210-DAA case for the large-capacity hook.). You'll adjust the bobbin tension differently for each size thread. It's better to have dedicated cases so you don't have to adjust back/forth. You can find these (often generic clones, cheaper) on eBay & Amazon. However, there is a bobbin-case I would avoid.

Needles

The machine uses 135x17 needles (also called DPx17). I use size 140/22 for all the webbing (both Tex-70 and -90 thread. Usually you'd use a larger needle with heavier thread.). It wouldn't hurt to have smaller 120/19, 130/21 & larger 160/23 needles. Ask the seller of the machine what would make sense to experiment with.

I use Groz-Beckert 768692 RG point (round with small ball point) SAN5 (which means improved thread guidance), "gedebur" (means titanium coated).

I started with Groz-Beckert 761032 R point (regular round point). They worked ok. The seller suggested SAN5 might work better. I think it does. When I switched to those, it seemed like the thread-tension balance (between needle and bobbin threads) was more consistent, less touchy. SAN5 has a larger channel for the thread. That might be why (the material isn't affecting the needle tension as much?).

Scheduled needle replacement

My first broken needles were due to things I did wrong. Eventually they broke after prolonged use (fatigue). The problem is: when the needle breaks, the remaining (jagged) shaft tears up the webbing (while the machine continues sewing until the last stitch of the pattern). It's a good idea to replace the needle after a certain amount of work. They only cost 50-cents. There's no reason to run them till they break. The challenge is to know when.

You can download a zipped spreadsheet to calculate how many stitches are sewn per collar or leash. (It was created using LibreOffice Calc). I make a certain amount of each item at a time. It's easy to enter that quantity in the spreadsheet to know how much work the needle has performed. (I can enter the work I intend to do, and know when the needle should be changed.). It seems like 75k to 100k stitches is a reasonable amount of work. After that, the risk of breaking is higher. (When I change the needle, I set the quantities back to zero.).

Alternative: the instruction manual (pg 35, "sewing through the use of a counter") discusses 3 types of counters available (per shape, per cycle & bobbin thread). The latter increments (or decrements) every 10 stitches. However, I found this feature wasn't reliable. I would set it to 7500 (75k). It would count down to 3000-4000, then jump to zero. Maybe this is fixed in a firmware update. But, I like using the spreadsheet better (the ability to project work that hasn't been done yet, and anticipate when to change the needle).

You won't need to think about this when you start. You'll break needles through mistakes before they wear out.

Lighting

You'll want more lighting than the machine's built-in light. You can buy gooseneck lamps that clamp onto the table, or you drill a hole & install permanently. There is a common design used with industrial machines (google industrial sewing machine lamps. You'll see lots of these). They seem to be called SNU-21, or SNU-26 referring to the length of the gooseneck. The -21 has a larger hood (6-1/2" long, 4" inside diameter at the opening) for use with an A21-size bulb. (Being shorter length, it can hold more weight? The SNU-26 has a smaller hood - 5-3/4" long, 3-3/4" ID - for use with a smaller A19 bulb.). Note: You'd only use a 40- or 60-watt (equiv) bulb in either fixture. Those brightness levels are available in either bulb size. But, if you use the larger A21 bulb in the SNU-26's smaller hood, it will protrude & be glaring to the eyes.

I installed a SNU-21 lamp each side of the machine:

The SNU-21 barely reaches on the left. The longer -26 might be a better choice. (Not just for the length, but the hood is a little smaller. The -21's hood feels a little in the way. If I did this again, I would start with -26 on both sides. The bulbs would be the same 40W-equiv brightness, just the smaller A-19 in a smaller hood. I think smaller hoods would fit better. But, it's important not to use the same A-21 bulb. It will protrude a little. To the extent you can see that protrusion, it will be glaring.).

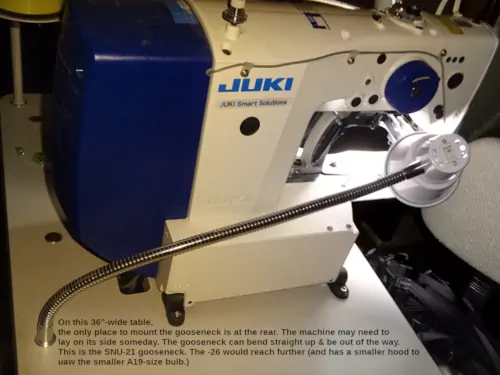

It's important to note that the machine may have to lay on its left side for service someday (warning: requires two people to safely tilt over). That lamp should be installed so it doesn't interfere with that. I.e, my table is only 36" wide. If the machine head tilted over, it would extend to the left edge of the table. I can' mount a lamp on that edge (except perhaps at the rear corner). For me, mounting the light directly behind the machine worked well. The light can bend straight up to allow the machine to lay on its side.

The machine comes with a built-in light with four brightness levels. It seems glaring to me. Putting some scotch tape over it might help (or tape some tissue paper over it).

Getting started

There is a bolt holding the machine down to the table (right-front corner. You can see it in the second lighting photo above.). This secures the machine from tipping over onto its side (which you might need to do for service, but takes two people. I believe the machine is top-heavy, and could flop over easily? If it did, that would be catastrophic.). You should loosen that bolt from underneath the table, but don't remove it. (It's useful as a safeguard against accidental tipping over. Just back the bolt out 1-2 turns. Leave the locknut loose, or finger tight against the machine.). Don't operate the machine with the bolt holding the machine down tight against the table. There are reports of the machine's base cracking due to vibration during sewing.

The machine comes with a clear plastic shield for eye protection (see instruction manual pg 23). If you wear glasses, you should be safe without it. Without any protection, if a needle breaks, a piece could strike your eye. If you wear glasses, consider their coverage (if anything could reach your eye). If you don't wear glasses, consider buying the weakest reading glasses sold at the pharmacy (0.75?). A little magnification could be good in addition to the protection. Otherwise, consider safety glasses, or installing the shield (whichever feels less intrusive).

When I started, I felt overwhelmed, and the fingerguard felt in the way. I removed it (until I used the machine for awhile). If you do that, be extra careful. The work clamp serves as a guard (only in the up position). It's not super unsafe to remove the fingerguard. But, it's better to have it on (I re-installed mine after 3-4 months when I was feeling better about everything.). The fingerguard can be raised or lowered. You can try to find a height that doesn't feel as in the way (but, be aware that the .).

You'll need to hold the thread when it starts sewing. If you don't, the white top thread will get pushed through to the bottom (the black side; called "piling?"). Pull the thread toward the rear of the machine until you have enough to comfortably hold. Then swing the end of the thread to the the front (toward you). If you don't, the the wiper arm will hit it (one of the reasons I removed my wiper arm. It's better to keep the wiper and learn to hold the thread this way). If you pull the thread toward you, it will be rough on the thread. You need to pull to the rear, then swing the end toward you. Fishing for the tail of thread around the needle made me nervous. Be aware of your foot on the pedal (not pressing down. Never put your finger under the needle. Just rub the side of the needle to get the thread.).

Sometimes the thread can loop over the top of the takeup lever. The symptom will be that it's hard to pull the thread (to the rear before starting to sew). If you don't realize it's looped, the thread tension will be wrong - the thread may even break; you could even break a needle. If it feels tighter when pulling the thread (to the rear, before starting to sew), look closely at the takeup lever to see if the thread is looped over it. But, also be aware that if the thread is pulling off the bottom of the spool, it can feel hard-to-pull too. The difference is that it will "give" freely when it gets past that. (You might feel that and think it's the takeup-lever problem. You'll get used to which is which.). I don't know why it loops over the takeup lever. It seems to happen when the pattern loads, the machine cycles into the ready state. I can go weeks without it happening, then it happens 10 times in a row.

There is a thread guide above the thread-tension disks. See the instruction manual (pg 15, threading illustration). Notice that the thread goes through that guide only once (up to the takeup lever). I started with the mistaken belief that the thread should also go down through that guide. After 4-5 months it stood out to me. When I started doing it correctly, it seemed like the machine operated better (thread tension was more consistent).

Things like this caused me to learn: if things aren't working right, stop & question everything. (I think my confustion is that some machines actually do go both directions through such a guide (my DU-1181N for leash sleeves does.).

The control box mounted under the table has a cooling fan. I live in a hot & dusty environment. I'm in the habit of blowing out my laptop 2-3 times a year (especially summer so it will operate cooler. It usually accumulates a lot of dust.). I thought this control-box fan would be similar. But, I've removed the plastic cover (4 screws), and haven't seen any buildup. (You can't see the fan. It's buried behind the circuit board. The parts list shows it. See "Control Box Components" part 17.). I'm still going to occasionally remove the cover and see if it needs to be blown clean. So far it doesn't have the problem I thought it would.

However: one side of that box is metal; seems like a heat sink. I use a 5" clamp-on fan (clamped onto the bottom foot of the table) to blow air onto that surface. You may not need to do this. Being in a hot environment, I'm in the habit of doing what I can to help electronics last longer. (I service this clamp-on fan 1-2 times a year by blowing the dust out of it; and remove the blade & plastic housing to apply some oil to the shaft's bearing surfaces. It will last many years doing that.). Juki's parts can be expensive. I'd do it in a cooler environment too.

Settings

Warning

The control panel has many options (called "switches") accessed by the "M" button. Press it once (one beep) and that's the options for normal operation. Hold it 2 seconds longer and you'll hear a 2nd beep. That gives you access to additional options. Hold it another 2 seconds for a 3rd beep gives more options. These options are listed in the instruction & engineer's manual. It helps to see them at a glance that way before seeing them on the control panel. (Juki's manuals are hard to understand. It doesn't help much.).

Don't play with these options (too soon, too many at once). Be sure to write down the value it was before changing so you can get back to where you were. There's probably a "factory reset" but I haven't had a reason to look for it yet. If you write everything down you shouldn't have to either.

It's easy to accidentally press the +/- keys intending to press the up/down arrow keys (to the prev/next "switch"), changing the value of the item you're still sitting on. If you think you've done that, power off (I don't think it saves until you press the return "↩" button. By "power off" I mean the power switch mounted to the table, not the green ready button on the control panel.).

One of first changes I made were K021 & 23 ("pressure switch positions 1 & 3"). These are in Memory Switch 2 (3 beeps). These specify the foot-pedal position to drop the work clamp, and to start sewing. The defaults are 90 & 230. I found it hard to hold the pedal between those two positions. I set these to 45 & 245. That gives more range (between the clamp coming down, and sewing starting). It can go to 250, but that didn't work reliably. Often it felt like I couldn't push far enough to make it start sewing. So, I backed it down to 245. (I haven't tried to find the highest number that will work, or to tighten the mechanical linkage to see if 250 would work.).

I definitely recommend that change. Operating this machine is overwhelming in the beginning. A lot happens all at once. Having more "wiggle room" for your foot definitely reduces stress. (Note: K022 isn't used. There is configuration of this machine that uses a "2-stage" pedal. It actuates something else between "clamp-down" and "sewing-start." You can ignore it.).

Also, I was stressed by the work clamp coming down. K027 (3 beeps, mem sw 2) sets the work clamp "lowering speed." I use 1,500 now. But, I started around 800. I would've gone even slower, but it sounds bad the slower it goes. (I don't think anything bad is happening. It just sounds like it.).

Winding bobbins

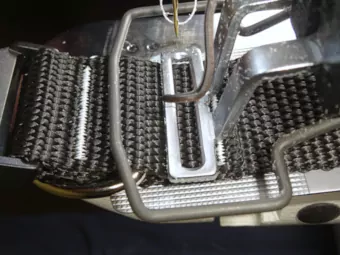

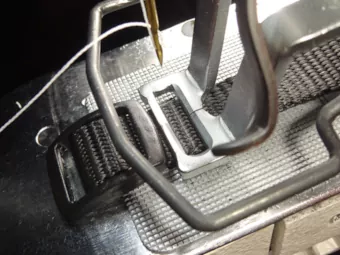

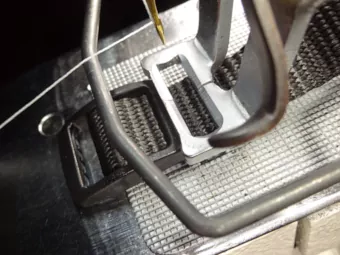

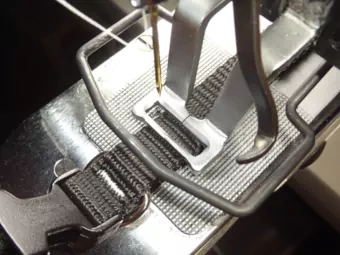

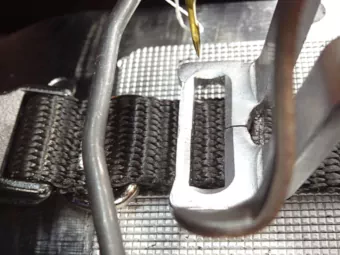

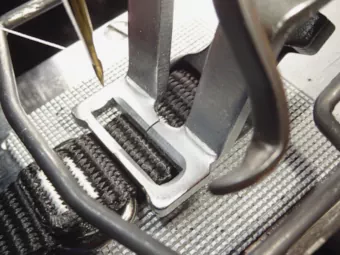

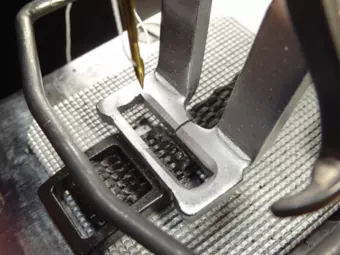

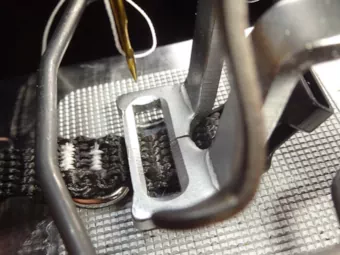

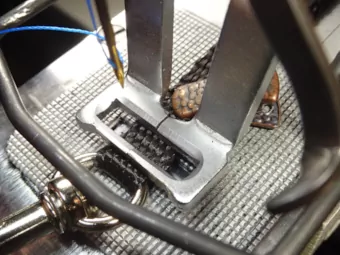

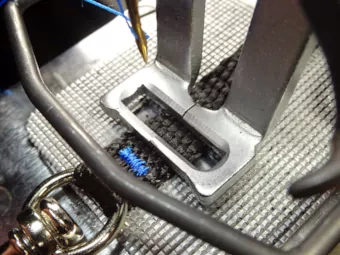

Winding bobbins with this machine is harder than others. The official(?) way is to wind the thread over/under a few times, and that will create enough friction to start. That didn't work for me most of the time. What works better is to drill a 3/32 (0.0938) hole in one side of the bobbin, near the center hole:

Smooth any burrs. You don't want the edge of the hole to snag the thread as it pulls off while sewing. (But, you don't want to roughen the inner surface of the bobbin trying to to remove any burrs. The inner surface should remain satin smooth. It's a little hard to do. You need something with hard, square edge you can get into the hole from the outside hole, and scrape that around the hole's inner edge. (Note: pictured is an aftermarket bobbin from eBay. It seems to work ok. If you have any problems with aftermarket parts, you should switch to the official part to rule that out.).

To wind a bobbin: push the thread through the hole, and slip the bobbin on the post (with the hole facing down). Then wind the thread around the bobbin a dozen times (clockwise looking down at it). Do that while holding the end of the thread (coming out the drilled hole. The bobbin pressed down on the winder's base will hold it a little, but you should hold the end of the thread with one hand while winding those first dozen times.). Then snip the excess thread as close to the bobbin edge as possible. (Even a little excess can interfere with the winding.).

After winding, you must snip the rest of the excess coming out of the hole. If you don't do that, any excess will cause the bobbin to pop out of the bobbin case while sewing. (It sounds really bad, like the machine is destroying itself.).

Another problem I had: it seems sensitive to the thread tension when winding. Often, the thread retracted into the bobbin case. It seems to be sensitive to being wound too tight (or loose). But, the engineer's manual (pg 68) talks about adjusting the "idling prevention spring" (a flat spring inside the bobbin that stops the bobbin from "racing."). I adjusted mine to be stronger. That may have helped.

I also increased both the thread & bobbin tension around the time this got better. When I started using the machine, it was easier to rip stitches (after a mistake, salvaging the materials) if the thread tension was loose. When I didn't need to rip stitches as often, I increased that tension. Maybe it was too low and that contributed to the problem.

But, it still seems like the winder tension can be too high (problems that seem like the thread doesn't come off the bobbin well). If you have trouble, loosen the winder's tension disks, try very loose. (Also make sure the excess thread is trimmed as close as possible before winding, and again before installing into the bobbin case. A small amount of excess can cause problems.)

Standalone bobbin winder

When I had trouble winding, I considered using a standalone winder which works with these bobbins (style A, class 15). This is the only one I could find:

That photo comes from Amazon (ASIN: B07RJL9XHY seller CKPSMS). You'll find many sellers of this winder. I chose that seller because their photos were more informative (instructional. The english is hard to understand. But, that was more than other sellers do.).

It works, but has some shortcomings (which wouldn't be hard to improve).[3] I only mention it because it's the only winder available. If you really need one, this works (and can be improved with some customization).

Control-panel bobbin winder

The control panel has a function to wind the bobbin (while not sewing) (instruction manual pg 23). But, the entire machine operates. That's a lot of wear & tear. I've done it when I had to, but wouldn't do this as the normal way to wind bobbins.

If you have to use this feature, be sure to unthread the machine past the takeup lever. If you don't, the thread can be pulled into the machine at the lever. That could take a lot of work to fix (removing the front & top covers of the machine, etc.).

I would use the standalone winder before doing this.

Installing a bobbin into the bobbin case

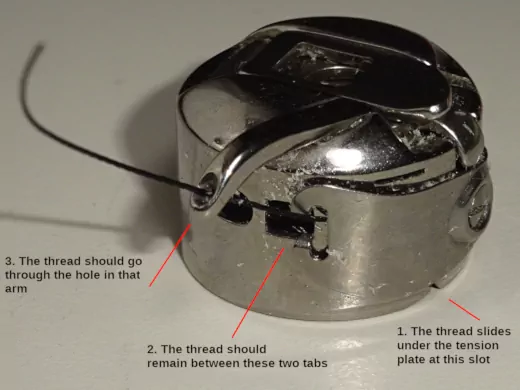

The instruction manual (pgs 15 & 16) shows how to install the bobbin. But, two things worth emphasizing:

The thread should go through the hole in case's arm. I didn't do that for 2 months. It seemed to work ok. (I somehow got the idea the needle went though that hole.). But, it's supposed to hold the thread for the needle and shuttle hook to bring together. I'm surprised how well it worked. I probably missed the first couple stitches and didn't notice it.

The tension plate (on the outside of the bobbin case) has two guides which the thread should stay between. If it's not between those guides, the thread tension will be inconsistent.

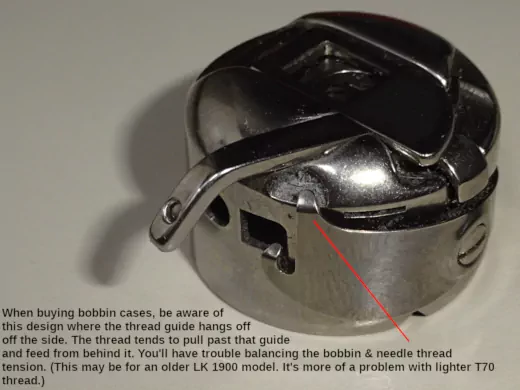

Bobbin case to avoid?

I bought a case on e-Bay that looks like this:

Notice how one of the guides (which the thread's supposed to stay between) hangs off the side of the case. The thread easily pulls past that guide, feeding from behind it - coming off the side of the tension plate. It wasn't a big problem. But, it's hard to get the thread tension balanced. You can find the other style (shown above, both "guides" go down into the square hole in front). This one may be an older design.

This one might work better with tex-90 (thicker) thread. Maybe that wouldn't slip past the guide as easily. My experience could also be due to me adjusting the bobbin thread tension to be pretty light. That means the tension plate is sprung higher, and the guide doesn't hang down the side of the case as far. Maybe that side of the tension plate could be removed & bent down a little to make that guide fit better. (FYI: I used light tension because whenever I made a mistake - like forgetting to install the d-ring before sewing the buckle-end - it was a lot of work to fix if the stitching was tighter. Having light thread-tension makes it easier to use a thread-ripping tool to "unsew" the mistake. I made a lot of mistakes in the beginning. This saved me a lot of time. But, couldn've contributed to this bobbin case not working as well.).

Work clamps & feed plates

The machine comes with a 27 x 5mm work clamp (27.4 x 5.2mm feed plate). You can use this for all the collar bartacks from 3/8"- to 1"-wide. (For the 1-1/2"-wide collars, you can sew two 3/4"-long bartacks end to end). This would be the fastest way to get started. But, my cut & mark measurements might not be right (at least for the smaller collars).

I bought a 40mm-wide clamp for the 1-1/2"-wide collar (one long bartack). And, a 20mm-wide for the 3/4" (and smaller) collars. My goal with the smaller clamp was to reduce the webbing's overlap (have more adjustable range. The 1" clamp would require more overlap with these smaller collars.). Previously, I made these collars with a Singer 201-2 which has a narrow foot. I was able to put the stitches closer to triglide, buckle, ring. The 20mm clamp (modified as you'll see) got closer to what I had been doing (than if I used the 27mm).

I use the following[4] with collars:

| Width | Clamp & Plate | Source |

|---|---|---|

| 1-1/2" | 39 x 6mm clamp & plate | eBay: CuTex Sewing Supplies |

| 1" | 27 x 5mm clamp & 27.4 x 5.4mm plate | came with machine |

| 3/4, 5/8 & 3/8" | 20 x 4.8mm clamp (modified) & 21.3 x 5.3mm plate | eBay: evernice |

For leashes you need box clamps. (The 3/8"-wide leashes are the exception. That webbing is the same as used for collars. Bar tacks are fine.). The webbing used for wider leashes is thin. If you tried to use a bartack, I think it should have a wider zig-zag (y-direction) than used for collars. The idea would be to cover more material. But, that could require you to enlarge the clamp & plate's opening (for a really wide zig-zag). If you had to do that, you might as well buy box-clamps.

I use the following with leashes:

| Width | Clamp & Plate | Source |

|---|---|---|

| 1" | 25 x 25mm clamp & plate | eBay: DailyDeal360 |

| 3/4" | 20 x 20mm clamp & plate | eBay: DailyDeal360 |

| 5/8" | 16 x 16mm clamp & plate | eBay: DailyDeal360 |

| 3/8" | Sew bartacks using the 3/8"-collar clamp & plate | |

Fitment

The inexpensive clamps I bought needed a little filing/polishing to fit into the arch's slots & slide freely. You'll need a polishing stone. I used a Harbor Freight Gordon Combination Sharpening Stone. It has a rough & fine surface. Be careful not to go too far, and make it fit too loose.

The clamps also tended to come down "toe-up" (the heel down more. That allowed some movement as the plate/clamp moved.). I placed mine in a vice (with a piece of wood protecting the polished surface from the vice's surface) and tapped them lightly with a hammer to align them a little better. Take your time, go slow. I tapped one clamp so far back (to bring the toe down enough to be flat) that the feed plate wouldn't go back far enough (it hit the arch's base). I had to grind some material off the end of the plate so it would move further back toward the arch's base. Be prepared. (Tapping the "thigh" of the clamp down won't move the foot back as much as tapping on the "shin.").

If the height of the two feet aren't the same, you can adjust the "lever driving plate:"

Those are screws I suggested having the seller loosen for you. Be aware: There is a real clamp-height adjustment under the machine's top cover (instruction manual pg 51). You shouldn't ever have to do that. These plates give you some overall height adjustment. You can use a dremel to elongate the holes even more than they are (for more adjustment).

Changing work clamps

As mentioned above (work clamps & feed plates), you can use the factory 27mm clamp for everything. But, if you buy clamps to better fit the different collar sizes (box-x clamps are almost a necessity for the thinner leash webbing), you'll have to change the clamps. Your choices:

Remove the faceplate

Remove the face plate (5 screws) to swap clamps. With the power off, you can push the arch back (and left/right) for better access to those screws (WARNING: Shoving the arch around can cause the fingerguard to hit the needle. There's a way to do it.). This isn't a way to do it, especially if you make a lot of one thing at a time (change clamps less frequently).

These are some of the screws I suggested you ask the seller to break free for you (and apply some anti-seize compound). The first time you remove the faceplate, if those screws are hard to turn, don't try to do it on the machine. Remove the arch & follow the instructions I gave there. If you round one of these heads off, it will be a lot of work to fix.

A downside to changing clamps this way: It's messy & tedious. Replacing the screws with philips or hex heads would make it easier (use a magnetic-tip driver). It will still be messy. You'll need to occasionally add grease because you'll lose some each time you swap clamps.

Dedicated arch assemblies

You can buy additional arch assemblies (have one for each clamp you use). Juki doesn't sell the arch assembly. You have to buy the bare arch and all the parts that attach to it. The bare arch (#400-39013) costs $70 (Jan 2026. The other parts probably add $200-$300.). That would get expensive.

I found someone selling used arches on eBay[5] for $75 (2025 prices). These appear to be real Juki arches. At that price, it seemed reasonable to have a dedicated arch for each clamp. (I needed five: $375. But, the seller's price includes shipping. I was able to "make an offer" for combined shipping & quantity discount. Maybe $60-$70 would've been fair.).

There are clone arch assemblies that aren't very expensive (example: Amazon ASIN B0CZ9PZ2FN is $65 in 2025). I think some clone parts are a good value. But, I'd be nervous about the arch. Note: that one says its for models that aren't the 1900-B or -BN. Remember: the "ball retainer" at the top is different for the -BN which has a sliding disk, not balls. (Be careful before buying a clone part.).

I started changing clamps this way. I'm happy. If I did this again, I'd consider removing the faceplate to change clamps. I make more of one thing at a time. I don't change clamps as often as I thought I would. Doing it the face-plate way wouldn't be bad. I spent $300 for arches. It might not be worth it. It's less tedious, and less messy.I think I jumped on it because I found these arches before I had my machine. I thought for $60-$70 each, I should grab those while I can (if the only option is $400 each from Juki. It made a lot of sense then. But, now that I've used the machine for a couple years. Removing the faceplate wouldn't be much work. I'd still view it as "what if these inexpensive used arches stopped being available? Would I kick mysle for not...?" It still seems worth it that way to me.

Important note about re-installing the arch: There is a small slider part on top of the arch. It sits inside an elevated cup (the "ball retainer" - which got its name from older models of the machine that used ball bearings in a cup. The cups may not be the same between those models and this one.). Make sure that slider sits flat (and that you didn't lose it). That slider can slip out a little, causing the arch to be cocked a little. If I'm careless and don't see it, then I notice it when tightening down the arch. Normally, the arch tightens down suddenly. If the slider isn't flat, then tightening the arch down will feel springy. You'll know it doesn't feel right. (It's probably not good for the arch, putting a stress on it to make it mate with the base it bolts onto.). It could be worthwhile to deliberately mis-align the slider to feel it, so you'll recognize it.

Likewise, when removing the arch be aware that you can easily lose that slider. It will often stick to the plate above it (due to the grease, which you may need to replenish over time). I worry it could fall and go inside the machine. I usually let the slider stay up there (I use the same slider for all the arches). But, I don't remove the feed plate until I install the reinstall the arch (or, I replace the feedplate before the arch.).

"Simple work clamp kit"

The brochure shows a "simple work clamp kit" (#400-57279). I've been told this costs $650 (Jan 2026), and that it's the entire arch assembly (but, the brochure says it doesn't come with the lever driving plates. The photo suggests it doesn't come with the ball-retainer cup on top.). The faceplate has its top cut off (so the clamp legs can lift up and out of the arch). The levers on each side allow their arms to retract out of the clamp legs. The arch has to be pushed to the rear for the clamp to slide up high enough to clear the faceplate. (The machine has to be powered off to do that.).

It's a good idea. Unfortunately, it's expensive for what you get. Still messy (the legs will be greasy; prone to getting dirty while out of the machine. You'll have to clean them before using again, and re-grease.).

Knurled-knob (finger-tight) faceplate screws

If I were starting again, I would pursue this idea. If the five faceplate screws were socket-head "cap screws" (the kind with the tall allen head, knurled around the side for easy finger-tightening) they'd be easier to work with. They'd probably need washers because the faceplate has the beveled hole. (The washers would probably have to be JB Welded onto the screw head so they're easier to work with, not lose.).

There's also specialty "knurled-head" screws. If the head were elevated by a shoulder (or, some of these have taller heads), they could be quickly finger tightened enough without using a tool.

The challenge is that these screws are 11/64" x 40 thread (8.7mm long). You probably won't find any of the above in that thread. But, you can buy a tap & die for that size. (ASIN: B09ZTTNP3Z). If you had a lathe, you could "turn" a larger screw down to the diameter necessary to use the die to cut new threads. (You'll need a "die stock wrench handle." The die linked above is 3/4" (20mm) diameter. You also need a "tap wrench handle" to use use the tap, for example: if you needed to "chase" the threads in the arch.).

You can also make something from threaded rod. 11/64" is 1/64" less than 3/16". Common #10-24 threaded rod is also called 3/16. I was able to cut good threads onto #10-24 threaded rod. The only problem is that this rod is a little larger than what you'd "turn" bar-stock down to (if you had a lathe). To use #10-24 threaded rod, you have to go 1/4" turn (then back 1/4" turn to clear the teeth. Use thread-cutting oil to flush the chips out.). It goes slow. (But, you only need to cut a short length of threads.). If you try to go faster - cutting further before reversing - the tap may not last long. Plan on short cuts, frequent reversing, and lots of cutting oil. (You don't need to buy real thread-cutting oil. Any oil should work. You're just flushing the chips out. I've read chainsaw "bar oil" is useful as a thread-cutting oil because it has high sulfur content which reduces binding.).

My idea was to thread a #10-24 knurled nut onto the threaded rod (the untouched threads, creating my own "knurled-knob" screw). Another idea: imagine bending one end of the threaded rod 45°, creating an L-shaped lever (a crank handle on the end). Using a #10-24 wingnut, cut one wing off. (Now you have two levers on the rod.). Screw the L-shaped rod into the arch. Cinch it tight using the one-wing wingnut (while holding the threaded-rod's lever end). This design would let you easily adjust where the wingnut's wing is positioned so it's out of the way of moving parts. Screw the rod in a little further/less so the wing-lever stops in an optimum position (neither lever in the way of anything).

HINT: #8-32 threaded rod is equally too thin (like #10-24 is a little too thick). But, it works. It will thread and tighten, but the threads aren't as substantial. This would be a good way to make prototypes. It cuts threads fast compared to #10-24. You just have to be careful to not cross-thread when starting to screw it into the arch. Don't overtighten. (It's a loose fit, but it works well enough to use.). When you find something that works, spend more time making that with #10-24 threaded rod.

Note: #8-32 bar stock (plain rod, not threaded) might work better. I haven't tried it. #10-24 bar stock is too substantial to cut these threads onto. The threaded rod has some material already removed. That makes it feasible to use. I assume #8-32 bar stock would have more material (which would make its threads better than cutting #8-32 threaded rod). But, #8-32 threaded rod would still be good for fast "proof of concept." The resulting cut threads work good enough for that, and you can cut them much faster to try something first.

Fingerguards

The machine comes with a 74 x 59mm fingerguard (#135-48300). There's a smaller 64 x 56.5mm fingerguard (#135-33104. I found mine on eBay.). It fits the smaller (20mm) bartack clamp.

Initially, I felt fingerguards were in the way. I removed mine. I re-installed them 2-3 months later after I was more acclimated to using the machine. The work clamp's feet are a "guard" in a way (while in the up position). It's not completely unsafe to go without. But, you have to be more careful. (When starting, you'll be uncoordinated with the foot pedal. You can reduce the risk of accidentally starting the machine by changing memory switches K021 & 23.).

For leashes (box clamps), I haven't tried the fingerguards yet. I believe those rectangular guards will work with the square clamps. Positioning the leash (shown below) doesn't involve putting your fingers as close to the needle as the collars.

If you use one arch, then you may need to change the fingerguard with the clamps (if you want to use the smaller fingerguard). Remember, those setscrews are tiny & hard to turn. Review how to loosen them the first time. Once that's done, they're easy to change.

Hint: the fingerguard can strike the needle when moving the arch. (I.e., there will be times you need to manually move the arch. When the power is off, you can push the arch around within its full sewing field, not just the pattern's travel.). You can install the fingerguard lower than the needle. But, you may want the fingerguard higher for larger collars. It's better to develop the habit of pushing the arch with both hands. Opposing force gives you more control - measured, slow movement. (Often, you can flex the fingerguard down enough to clear the needle. But, you need two-handed control to get close first. One-handed movement doesn't work.).

Making collars

The machine comes with 50 "standard" patterns (shown in the brochure). I use those for the collars. The following are the details I use:

| Webbing | Pattern Key | Std Pattern | Stitches | Scale % | Speed | Thread tension | |

|---|---|---|---|---|---|---|---|

| x | y | ||||||

| 3/8" | P1 | 12 | 28 | 92 | 80, 90 & 105* | 800 | 70-80 |

| 5/8" | P2 | 08 | 36 | 65 | 94 & 102† | 900 | 63-73 |

| 3/4" | P3 | 03 | 42 | 95 | 110 | 1100 | 75-85 |

| 1" | P4 | 09 | 56 | 79 | 92 | 1100 | 65-75 |

| 1-1/2" | P5 | 37 | 90 | 140 | 100 | 1100 | 64-76 |

The instruction manual (pg 27) explains how to register a standard pattern to a "pattern key."

Thread tension

My thread tension probably won't work for you. The tension you use will depend on a few things:

The tack next to the melted ends requires a higher thread tension.

If your bobbin tension is higher, then your needle tension will be too (for "balanced" stitches - the white thread doesn't pull through to the black side).

Note: if you have higher thread tension (because the bobbin tension is higher), it will be harder to rip the stitching (with a thread-ripping tool). When I started, I made a lot of mistakes (forgetting the D-ring, etc.). A looser thread tension is easier to rip. I set my bobbin tension lower (which necessitated a lower needle tension for balanced stitches). After a few months I made fewer mistakes. I increased the bobbin tension (which necessitated higher needle tension). I think that works better now. I had some bobbin-feeding problems when I had lower tension. I think I get better cut thread now too. (It's hard to say. I changed a couple other things at the same time. Be aware that there might be a "too low.").

Each webbing (product, size) requires its own thread tension. There may even be variations between rolls (batches) of the same product.

For any of the buckle-end tacks: if I run out of bobbin thread, I'll increase the tension 20% when I sew over that partial tack. Sewing over a partial tack can cause the white thread to pull through to the visible side. More tension reduces that. (You may still need to use a Sharpie pen to blacken any white thread so it doesn't show).

I mention the buckle-end because: if the white thread pulls through, it will visible. The same can happen with the tri-glide end (if I run out of bobbin thread sewing those tacks). But, it doesn't show (it's under the collar). I don't care about that much. If you care, then you can use a higher tension on the tri-glide end (when sewing over a partial tack. Also when sewing the tack that's closest to that melted end.).

When you start using the machine, you'll make one collar at a time. At some point, you should shift to sewing all the tri-glide tack(s) first. Then install all the loops & male buckles. Then, sew all the buckle ends (the tack nearest all the buckles first; then all the melted ends. Finally both sides of the D-ring at the same time.). That goes faster than making one at a time.

Clamping onto the tri-glide

For the bartack closest to the tri-glide: you'll see that I drop the clamp onto the tri-glide. You shouldn't start this way. Add 1/4" to the cut length (give that to the tri-glide overlap). Then just sew with the clamp on the webbing. Your finished collar's adjustable range will be a little less. But, much easier to sew.

Clamping onto the tri-glide caused me a lot of trouble (for a long time). I still do it because I found a technique.[6] You might want to try it eventually, but it's not worth the trouble when starting.

The following sections show what the different sizes of collars look like (with their clamps). I discuss more topics along the way:

1-1/2"

Material moves under clamp

This topic applies the most to the 1-1/2" collar due to its weight. What I found is that pinning the webbing against the feedplate screw solves the problem. (I provide more info about this technique in the footnote to clamping onto the tri-glide.). It makes the webbing solidly part of the moving feedplate & arch. I don't have to do it with everything. It helps with the larger collars.

For the smaller collars, I might push down on the plate (not the screw). They don't need as much help (they don't vibrate as much). Or, I might suspend the webbing lightly in my hand, trying not to add any tension or weight to what's under the clamp.

The last tack requires the webbing point towards you. Just lightly suspend that, giving it a lot of slack so the clamp can move around without the material resisting. You can do the same thing when the material points to the rear. But, for some things it works better to hold it down tight on the plate - and even better against the screw.).

Other factors:

I mentioned in the clamp-fitment section that the clamp's I bought were a little "toe-up". I wouldn't have noticed if I didn't have some slippage causing me to examine everything more closely. I removed the feet from the arch, put them in a vise (using wood not to mar the feet) & tapped with a hammer (very little) to change the angle. Go slow, put them back in the arch and check. It's tedious. But, I think this helped. (You can tap the "shin" or the "thigh" of the clamp. The shin makes the foot go back when becoming level. The thigh causes the foot to go down as part of becoming level. A little of both may be best.).

The zig-zag width (y-scale) of the bartack can make it worse (more front/back movement). Also, stitch speed can "resonate" with (amplify) the machine's movement. A slower or faster speed can help. For the larger collars, letting the end of the collar hang off the table can amplify the vibration. It can help to lay the end on the table.

When sewing the buckle end, it's possible to clamp too high up against the buckle (or the D-ring). When sewing starts, it will slip down (revealing the the straight basting stiches outside the zig-zag). Wag the webbing side-to-side a little to let the clamp settle if it needs to.

That last point (about clamping too close to the buckle or ring) caused me to grind some of the front off the 3/4" clamp (shown below) so I can clamp closer to the buckle & ring. I'm tempted to do that with this 1-1/2" clamp (and 1" too). It could be better. The clamps I bought were inexpensive. It wouldn't be risky to try. (I wouldn't do this with the 1" clamp the machine comes with. Original Juki parts are expensive. I'd buy an aftermarket 1" clamp to experiment with.).

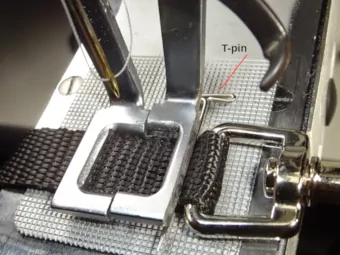

1"

This uses the clamp & plate the machine came with. The photos are in the order of operations: 1) Tack the tail of the tri-glide end. 2) Tack next to the triglide (I clamp onto the triglide itself. You can see the first tack through the opening because the foot is elevated. Remember: I urged you not to start this way.). 3) At the other end: tack closest to the buckle. Then, 4) the tail, 5) the tail-side of the D-ring, and 6) the other (buckle) side of the D-ring:

3/4"

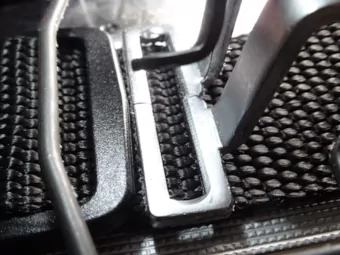

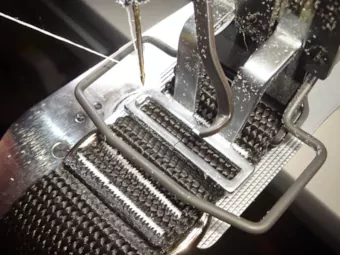

Notice I ground off some of the front of the 20 x 4.8mm clamp I bought on eBay:

I used a dremel with a "cutting wheel" (lightly going back/forth against that surface, taking the material down to what you see. These wheels are made for cutting through things, not grinding. They're very delicate and break easily. You have to lightly drag the edge of the wheel along that surface. It goes slow. Be focused on getting a straight edge and not going too far.).

When I started, this was the clamp for the 5/8" & 3/8" collars (so I could get the stitching into a smaller space). But, I found that this clamp works better for the 3/4" too. Especially for photo #2 (clamping down onto the tri-glide - which I've already explained you shouldn't do.). The unaltered 20mm clamp didn't work well on top of the tri-glide. This one grips better.

If you ever tried clamping down on the tri-glide, this collar is the last one to try that with. (It gave me the most trouble.).

5/8"

The -Short collar has just one bartack at the tri-glide. Skip the first photo (which shows sewing the tri-glide tail of the -Long collar).

If you ever try clamping onto the tri-glide, this collar is the easiest. The -Long is easier than -Short because it's a little harder the overlap straight when the first tack is done from the tri-glide. You have to not only get it clamped on just so, but also get the overlap lined up with itself. That's easier to do when sewing the tail. Then when you sew the 2nd tack clamped onto the tri-glide, you have less to deal with.

Short

I sew just one bartack at the -Short's tri-glide. I increase the zig-zag height (y-scale). (See the table of pattern settings). Enlarging the zig-zag seems like a good idea (to use more of that space). But, don't forget that it could cause the needle to strike the feedplate. (Be sure to double-check how the pattern fits the feedplate's cutout. See instruction manual pg 21, "Checking the contour of a sewing pattern."). If you clamp onto the tri-glide the way I do: a larger zig-zag increases the chance of the needle striking the tri-glide. (Also, more travel can mean more vibration - which increases the risk of the tri-glide moving under the clamp. It can slip & be struck by the needle. Or, the foot can slip entirely off the tri-glide.).

Note: My choice to start using 2 tacks at the tri-glide with the 5/8"-Long was completely arbitrary. I've mentioned elsewhere that two tacks is probably overkill even for the 1-1/2" collars. Almost no force reaches those stitches. (Think about how the webbing loops through the tri-glide like a pulley. There's much less force reaching those stitches compared to the D-ring's stitches.).

I like the security (redundancy) of two tacks. I.e., I can't see myself doing just one tack with the 1-1/2" tri-glide (even though I'm sure it's strong enough). Then it turns into where to draw the line. It's obviously over-kill for the 3/8" collars." I chose 5/8"-Long as the collar to start using two tacks. You could easily decide that one's overkill too. There's no right answer. I choose to err to the side of overkill.

3/8"

Both the -Long & -Short collars use just one bartack at the tri-glide (like the 5/8"-Short above):

I increase the zig-zag height (y-scale) for this stich (see the table of pattern settings). My comments about the 5/8"-Short's single-tack tri-glide apply here too.

If you ever try clamping down on the tri-glides, The 3/8" is easier like the 5/8" is. But, as I mentioned with the 5/8": sewing just one tack makes it a little harder (because you also have to get the overlap aligned. It's more to deal with compared to two tacks - the first at the tail which is easier to get the webbing aligned before trying to clamp onto the tri-glide.).

Long

The -Long collar has two bartacks each side of the ring (like the larger collars):

I use the lowest zig-zag (y-scale) for those. See the table of pattern settings.

Short

The -Short collar uses just one bartack each side of the ring (at the buckle first, then the tail):

Like the single-tack tri-glide: I increase the zig-zag (y-scale) of this single-tack too, but not as much. See the table of pattern settings.

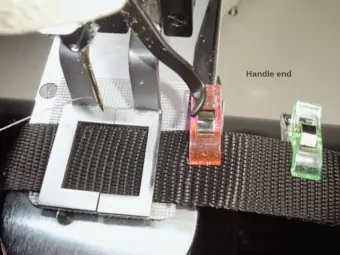

Notice that I use a smaller clip to hold the tail (when sewing the first tack at the buckle). That's a very tight fit to get an ordinary plastic sewing clip into that space behind the work clamp. These clips are called "Mini Alligator Clips" (I bought Amazon ASIN: B0F2T9YJH6.). The ones I bought have a silicon mouth (insert) inside the metal clamp. Some of the other sellers seemed to show a photo of a clamp without that insert. I think the silicon grips better. (These might even work better than the common plastic clips. Those clips stress from repeated use, and break after some use. They're cheap; it doesn't matter.).

Making leashes

| Webbing | Pattern Key | User Pattern | Stitches | Scale % | Speed | Thread tension | |

|---|---|---|---|---|---|---|---|

| x | y | ||||||

| 3/8" | P1* | 120 | |||||

| 5/8" | P7 (P1+P3) | 151 | 84 | 52 | 46 | 900 | 58 |

| 3/4" | P8 (P1+P4) | 151 | 84 | 66 | 57 | 900 | 51 |

| 1" | P9 (P1+P5) | 153 | 110 | 54 | 63 | 1000 | 50 |

Box-x patterns

The machine doesn't come with box-x patterns. This zip file contains the patterns I use. You can put them on a USB, then copy them into the control panel (the numbers 150-153 are the pattern numbers where mine are stored). The instruction manual (pgs 42 & 43) talks about how to do this. (Ask the seller of your machine to do this for you.).

The zip file contains two box patterns (150 & 152) and two box-x. I don't know what the box-only patterns would be used for. Sometimes you see box-x stitching with two lines of stitching on each end. I think you can use 150 with 151 (152 with 153) to get that kind of pattern. This would be done with the "combination function (cycle sewing)" discussed in the instruction manual (pg 32). You would sew the box, then the box-x inside. It would happen in one operation. (For leashes this is overkill. The box-x by itself is fine. It has two lines of stitches at each end.).

The collar's thread-tension topics apply here too. The only difference is that I use gray & charcoal thread instead of white. If the thread isn't balanced, it's not as visible as the collar's white thread.

I never have any problem with the material moving (as it can making collars). I suspend both ends as it sews so it doesn't drag or hang. (This is more concern with the metal bolt-snap. The plastic clips used on the handle-end could snag too if they're too close.).

1"

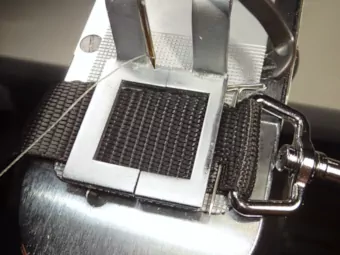

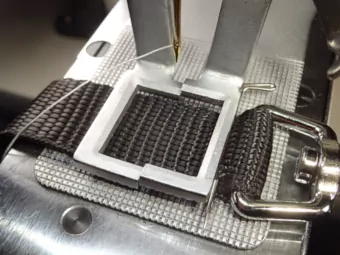

The following shows the Regular leash (with charcoal thread. I make a Heavy version with amber/ochre thread to denote a heavier snap.):

For the snap end: I use a "T-pin" (1-1/2" long).

Notice that I ground off some of the clamp's right side to make it narrower. (I used a Sharpie to mark the edge so I could see how much I ground off as I did it. You can still see that mark.). That modification lets me sew a little closer to the bolt (allowing the overlap to be this much less). You don't have to do this, but you'll need to mark a longer overlap. It might not look right with the box further from the bolt.

Lining up

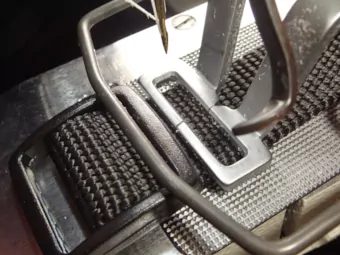

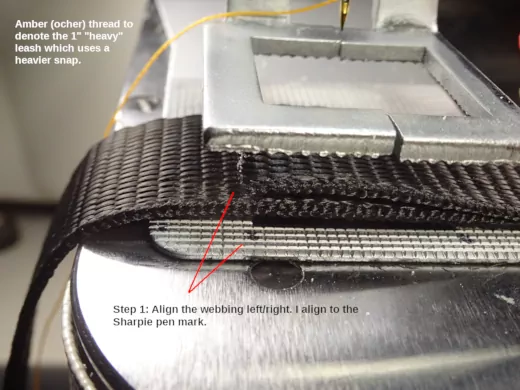

It's challenging to align & center this. First of all, you should draw Sharpie lines on the faceplate showing the edge of the cutout. When sewing, you have to pay attention to three things.

1) I clamp-down once (and release) to flatten the webbing. Then I move the webbing left/right. I look at the front mark, and position the webbing so the melted end extends far enough past the cutout:

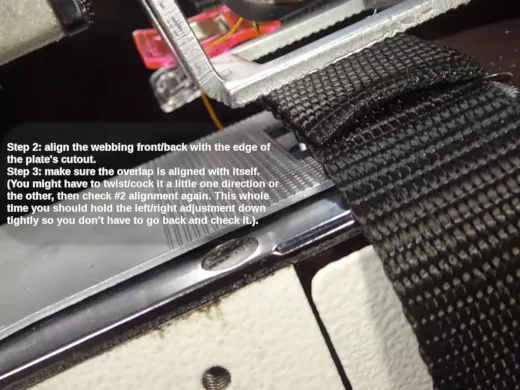

2) I hold my head to the left side, and move the webbing front/back. I look at the side marks, and position the webbing between those:

3) Make sure the two layers of webbing are stacked squarely (the melted end doesn't overhang one or other side). Pulling it tight helps align the layers. But, then you have to do #1 & 2 again.

This goes slower than collars (but, you only sew twice. You sew the collars six times.). Take your time. Double check. This would benefit from guides attached to the feedplate.

The control panel (where you set the speed, x-/y-scale, etc) allows you to adjust the x/y position. I adjust the y-offset a lot. When I position the webbing (per above), even though it looks centered to me (front/back), the box comes out uncentered. You can either make a mental correction to your positioning, or change the y-offset so it comes out as you think it should. (I go back forth between mental and offset. The risk of doing that is: you might chase it around if you don't settle on one way of looking at it, doing it.).

3/4"

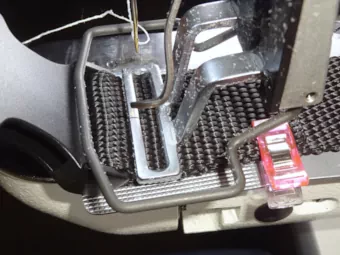

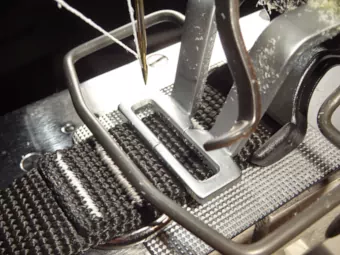

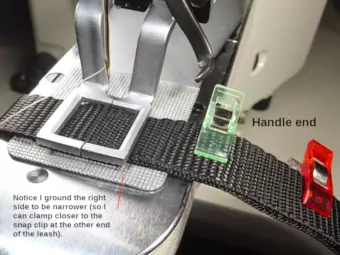

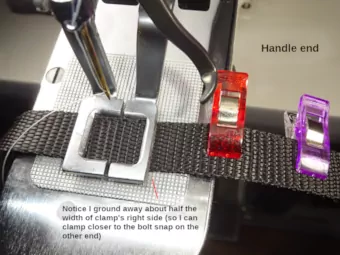

Notice I ground down the right side of the 3/4" clamp too:

I draw better Sharpie lines now. I use a "fine-tip" Sharpie which will fits the groove, will draw the line in the groove. I draw them following the groove all the way to the edge. They stand out very well, and are very precise markers for aligning. I started with an ordinary fat Sharpie. It's hard to get an accurate mark.

5/8"

3/8"

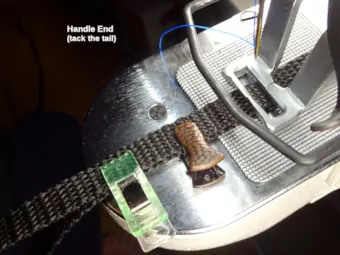

I sew the 3/8" leash like I do the 3/8" collar (with bartacks). The same webbing is used for both. (I think it would be hard to sew a box-x this small.). I start with the handle end, tacking the tail first, then the handle opening. I try to space the tacks 1/2" apart:

The snap end is similar, but I sew the tack closest to the snap first (with the webbing tail clipped in place. Then I sew the tail:

That small clip barely fits behind the clamp. I provided more info about that clip in the 3/8"-Short collar section above.

These photos show the Light version (using blue tex-70 thread signifying a lighter-weight bolt-snap). I make a Regular version using "shark gray" thread (to denote a stronger bolt-snap.).